HOT SPRINGS -- Arkansas-based Alliance Rubber Co., the nation's largest rubber band maker, is tightening its grip on the market with the addition of products under Staples' private label this fall.

The family-owned and operated company already has a portion of Staples' business, providing products for the retailers' catalog sales since 1988. Alliance also is a supplier to global retail giant Wal-Mart, the U.S. Postal Service, The Container Store, the combined Office Depot-OfficeMax and agricultural growers who use bands to bundle produce such as broccoli and asparagus.

Alliance produced 15 million pounds of rubber bands and other products in 2014 and is on target to produce 18 million pounds over the next year with the added Staples business, said Jason Risner, marketing manager for Alliance. A third shift will have to be added, he said.

Even then, the 150,000-square-foot plant won't be operating at capacity, as it did in the early 2000s, when Alliance was producing about 25 million pounds of product per year. The reason for the decline: turmoil in the newspaper and postal industries. To help counteract the decline, Alliance has had to reinvent itself with innovative offerings.

"We've stretched the limits of what you can do with rubber bands, with what you can do with extruded rubber," Risner said. Extrusion is the process of creating rubber tubing in a defined shape by forcing uncured material through a die.

"We can print on them, we can add fragrance to them, we can make them glow in the dark -- we've hit almost everything there is," Risner added.

In October 2013, Alliance Rubber's Eraselet, a bracelet made of erasers, was a finalist in Wal-Mart's Get on the Shelf contest, a competition for inventors hoping to get their products on walmart.com. The Eraselet didn't win, but it gave Alliance -- a Wal-Mart supplier since 1973 -- more name recognition and clout when it attended Wal-Mart's first "Made in the USA" Open Call to vendors last July. Suppliers schlepped their products to the global retailer's Bentonville headquarters to meet with senior leaders and merchants to pitch their products.

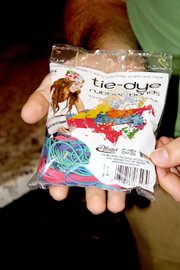

Two years ago, Wal-Mart made a commitment to buy millions of dollars more in domestic products with the goal of onshoring foreign manufacturing. The retailer has carried the standard 2-ounce and 4-ounce packages of rubber bands made by Alliance but recently added a half-pound bag, as well as colorful bands made specifically for tie-dying items.

Wal-Mart had been buying the craft bands from a supplier in Thailand and approached Alliance at Open Call with the idea for making them in Hot Springs, said Sheryl Koller, national sales representative for Alliance.

Alliance soon will be offering products to be sold in the automotive and hardware departments on walmart.com.

"We've got a lot of different irons in the fire from that meeting," Risner said of last year's Open Call. This year, Wal-Mart is combining its U.S. Manufacturing Supplier Summit and Open Call into a two-day affair July 7-8 in Bentonville.

The latex rubber made into bands at Alliance is harvested from trees in Indonesia, Thailand and Vietnam, among other places. Trees must be seven years old before the rubber is harvested, and the trees will produce the byproduct for another 28 years once it begins to yield.

"The material that we use, which makes up anywhere from 60 to 88 percent of the rubber band, is considered a renewable resource," Risner said. Alliance exports to some 55 different countries, with those sales representing close 10 percent of its business.

The privately held company was founded by William H. Spencer in Alliance, Ohio, in 1923, but has had a presence in Hot Springs since 1944. The company's sales and other operations moved from Franklin, Ky., to Hot Springs in the 1990s. The company now is run by Spencer's daughter, president Bonnie Swayze, with help from a third generation -- nieces Michelle Hitt and Brandi Spencer. Swayze's sons Billy and Beau Swayze also have an ownership interest in the company, though Swayze's mother, Anna Jean Spencer, owns the majority of the business.

Swayze said her dad moved his company to the spa city because he liked the hot springs baths.

"My brother and I were drafted into the business at a young age," Swayze said. Alliance employs some 178 people in Hot Springs with less than a 5 percent turnover rate last year.

"The innovation, the ingenuity and the extremely strong work ethic is what enables us to stay competitive," she said.

In order to compete with imported product -- produced using labor at only a fraction of what the Hot Springs plant pays -- much of the band-making processes are automated. Wages for the Hot Springs company are more than 11 times what companies in Thailand and China pay, benefits notwithstanding, Swayze said. Some 80 percent of the company's managers started on the company's manufacturing floor.

In addition to rubber bands, Alliance makes rubber wrist bands and wide elastic strips used for exercise and rehabilitation, with ability to print full-color, digital-quality graphics on the bands. The ad specialty segment is the company's smallest, "but it's where a lot of our cooler stuff is sold," Risner said.

SundayMonday Business on 05/17/2015