Pipe-seam failures rare but damaging

Ruptures are gushers, expert says

Sunday, August 11, 2013

Ruptures of long seams in old oil and gas pipelines, like the one that dumped some 210,000 gallons of heavy oil into a Mayflower subdivision in March, account for as few as 4 percent of all U.S. pipeline failures, experts say.

But those spills also rank among the most damaging and deadly pipeline accidents. The seams burst open in a flash and typically discharge large quantities of hazardous liquids or natural gas.

“It happens in microseconds,” Richard Kuprewicz, a pipeline-safety consultant, said of Exxon Mobil Corp.’s Pegasus pipeline blowout at Mayflower and similar accidents. “It doesn’t start with a leak. The nature of this is to blink and you’ve got a rupture.”

RELATED ARTICLE

http://www.arkansas…">Details from federal study on seam ruptures emerge

Since 2009, U.S. pipeline-safety regulators have pushed the pipeline industry to identify which decades-old oil and natural gas pipes are likely to fracture at their seams so companies can strengthen or replace them before they break.

The federal pipeline-safety administration is awaiting results from a three-year, $4.15 million study of the issue. The goal is “to eliminate catastrophic longitudinal seam failures,” according to an Oct. 27, 2009, letter requesting the study from National Transportation and Safety Board Chairman Deborah Hersman.

In the aftermath of the pipeline-seam break in the Mayflower subdivision about 22 miles northwest of Little Rock, regulators and safety experts also await the investigative findings from that spill, hoping for answers to a problem that spans decades.

‘SPREADING FAST’

The March 29 Pegasus pipeline rupture in the Northwoods subdivision was a good example of what happens when a pipeline seam breaks, said Kuprewicz, who is advising Central Arkansas Water as it reviews risks associated with the pipeline’s presence in the Lake Maumelle watershed.

“That opened up a 22-foot line,” or crack, in the 20-inch diameter pipeline, Kuprewicz said. That type of break means “bigger openings and higher flow rates, whether gas or liquid.”

Faulkner County sheriff’s office records suggest how much heavy, sticky Canadian crude oil poured from the underground pipe and how quickly it spread through two residential streets.

The first homeowner to call 911, at 2:43 p.m., said the oil pipeline running through her yard had burst, county records show.

Six minutes later a Faulkner County dispatcher noted reports of oil gushing through the streets: “Evacuating homes at this time … the oil is spreading fast … storm drain is backed up.”

Ultimately, 22 families abandoned their homes at the height of the spill as it spread through the subdivision streets and into a cove of Lake Conway, a popular fishing spot.

Seam failures like the one in Mayflower have been the focus of safety notices issued by the federal Pipeline and Hazardous Material Safety Administration for at least 25 years.

The agency has singled out pipe manufactured before 1970 that used low-frequency, electric-resistance welds - exactly the type that separated on the Pegasus pipeline, according to test reports.

The pipe was manufactured in the 1940s using low-frequency electric current to join the edges of steel sheets rolled into a cylindrical shape. The manufacturing process was abandoned after 1970 because the seams proved to be “susceptible to selective seam corrosion, hook cracks, and inadequate bonding of the seams,” according to the pipeline-safety agency.

THE PIPE

In the 1980s, the pipeline-safety agency’s bulletins concentrated on how often those pipeline seams burst. Officials logged “12 hazardous liquid pipeline failures” along pipe seams in 1986 and 1987.

But in recent years, regulators have shifted their focus from the number of accidents to their toll in damage and even death.

Two years ago, a Pipeline and Hazardous Materials Safety Administration conference on “Managing Challenges with Pipeline Seam Welds” showed the change in view. The Washington, D.C., conference on July 20, 2011, drew about 250 industry, government and private-sector pipeline experts.

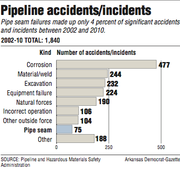

Speakers talked about how pipeline seam failures were declining, totaling 75 significant spills between 2002 and 2010, and accounting for about 4 percent of 1,840 total pipeline failures.

Even so, regulators called for “new focus on the consequences of failure from seam threats,” according to a report of the meeting posted on the pipeline-safety agency’s website.

Conference organizers asked for “targeted policy, investments in research to improve technology, and additional training by the greater pipeline safety …. community.”

Those efforts were driven in part by two deadly pipeline-seam accidents since 2007, experts say.

One raised concerns that existing tests might not be reliable enough to predict pipe-seam failures. That worry came out of a Carmichael, Miss., spill on Nov. 1, 2007, that involved old low-frequency, electric-resistance welded pipe. The broken pipe shot out liquid propane that formed a cloud and then ignited, killing two people.

The operator, Dixie Pipeline Co., had conducted numerous inspections over the previous nine years. Those tests found “no defects” that would have predicted the breach, according to a report from the National Transportation Safety Board. The board oversees the pipeline-safety agency and carries out major pipeline-disaster investigations.

A second high-profile pipeline break raised different questions about pipe-seam safety tests - whether some pipeline operators were conducting them properly.

On Sept. 9, 2010, a 30-inch natural gas pipeline operated by Pacific Gas and Electric Co. ruptured in a residential neighborhood in San Bruno, Calif. The escaping gas burst into a fireball. Eight people died, many others were injured and at least 38 homes were destroyed.

A federal investigation showed the San Bruno rupture happened where pipeline-company workers welded several short pipes together in a 1956 relocation. Those pipes didn’t meet industry specifications, the safety-board report said. The investigation also found pipe seams that had been faulty since their manufacture, with “partially welded longitudinal seams.”

Federal investigators cited Pacific Gas and Electric for “a litany of failures” in the San Bruno disaster, including installing inadequate pipe 55 years earlier and failing in the decades afterward to detect the flaws. Investigators also blamed state and federal regulators for lack of oversight.

‘LOOKING TOWARD MAYFLOWER’

In July, the Arkansas Democrat-Gazette obtained the conclusion of a report by Hurst Metallurgical Research Laboratory of Euless, Texas, on the condition of the failed Mayflower pipeline segment.

The pipe section had opened up on a longitudinal seam, the report said. Tests found familiar problems with old low-frequency electric-resistance welded pipes, including manufacturing defects in the seams.

The lab also found characteristic “hook cracks” more than 13 inches long, raising questions about when the cracks occurred and whether they should have been discovered earlier, experts say.

Records on the Pipeline Safety and Hazardous Materials Administration website indicate that Exxon Mobil has conducted safety tests and inspections numerous times since 1994 on the 850-mile Pegasus line, which stretches from Illinois to the Texas coast.

In 2006, the company conducted a hydrostatic test, which uses water pressure, and found no problems on the Mayflower section, according to that report. That test was conducted so the oil company could restart the pipeline, which had been idle since 2002.

Carl Weimer, director of the Pipeline Safety Trust of Bellingham, Wash., said pipeline-safety experts are looking to the Mayflower spill investigation to help the industry and regulators understand and eliminate the long-running problem of seam failures in oil and natural gas pipelines.

One Exxon Mobil test they’d like to review was carried out in February, just weeks before the rupture, Weimer said.

Exxon Mobil spokesman Aaron Stryk said last week that “we are still validating the data” of that study. The pipeline-safety agency said last week that it also was still evaluating the February test results.

“It will be interesting to find out if the in-line inspection on the Mayflower pipeline [in February] showed there were problems or not,” Weimer said.

“People are looking toward Mayflower.”

Front Section, Pages 1 on 08/11/2013