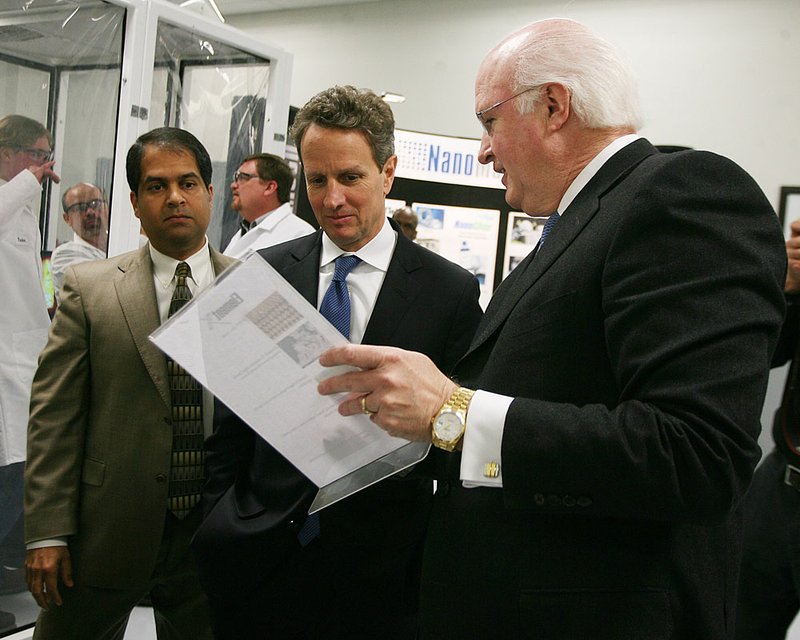

SPRINGDALE — U.S. Secretary of the Treasury Timothy Geithner, in his debut appearance in Northwest Arkansas, said Friday that the administration will attempt to help spur research and development at companies of all sizes through an expanded, and permanent, tax credit.

The former president of the Federal Reserve Bank of New York commented on the research and experimentation tax credit after a tour of nano-materials manufacturer NanoMech - a business expected to benefit from the federal incentive.

Geithner, who spent half a day in Arkansas, said he hopes more businesses can do what NanoMech founder Ajay Malshe did, which was to take an idea and turn it into a job-producing company.

Malshe, the 21st century endowed chair professor of materials, manufacturing processes and integrated systems at the University of Arkansas at Fayetteville, founded Nano-Mech Inc. in 2002 as a nanomaterials and manufacturing business.

The company employs about 30 people between locations in Springdale and the UA-affiliated Research and Technology Park in Fayetteville.

NanoMech has said its work force will double and new equipment will be purchased as a result of employing the tax credits.

A tax credit, unlike deductions that get subtracted from income, is subtracted from the amount owed to the Internal Revenue Service, James White, an economist specializing in taxes with the U.S. Government Accountability Office in Washington, D.C., said this week in a telephone interview.

The research and experimentation tax credit represents a “windfall” to most companies that use it, because “it gives them a credit for research spending that they would have done anyway,” White said.

Companies claiming such a credit in 2009 resulted in a tax-revenue loss of $5.6 billion, according to the accountability office, which is billed as a nonpartisan congressional agency.

To be a more effective economic development tool, a tax credit should stimulate research that would not have been done otherwise, White said.

Tax credits, in general, are not stimulating new research, White said, they aren’t “creating anything, jobs included.”

And such indirect subsidies have been criticized among start-up companies, because it can take firms a few years to earn a profit and to be able to pay taxes.

For eligible businesses, however, the administration proposes expanding the tax credit originated in 1981 by 20 percent and making it more accessible for businesses touse. Numerous proposals for a permanent extension have been made in Congress, Treasury officials said.

“We released a report today on the economic benefits of this kind of incentive in helping support more than $100 billion in innovative research and nearly 1 million research workers in professions that pay a good salary,” Geithner told a small audience assembled in a manufacturing bay at NanoMech’s facility.

Before his tour of Nano-Mech, Geithner had an opportunity to visit with as many as 15 different businesses at the Arkansas World Trade Center in nearby Rogers.

Officials said representatives from Wal-Mart Stores Inc., Arvest Bank, Tyson Foods Inc., among others, were invited to the private event.

Jim Phillips, NanoMech’s chairman and chief executive officer, said in a previous telephone interview that commercialization of NanoMech products is happening at full speed.

“We’re commercially ready for prime time,” he said crediting chief technology officer Malshe, a native of India, as helping to bring back meaning to “Made in America.”

Countries such as China, Russia and India are “after a leadership position in this,” Phillips said. “But we’re not going to let that happen in nano.”

NanoMech first marketed itself through its Duralor subsidiary which makes a cubic boron nitride coating for machine tools used in metal cutting applications.

The business has gone on to tout its lubrication for machines, body armor, as well as develop a number of other applications for energy, agricultural and biomedical industries.

More recently the company said it acquired Canadian Nano Technologies LLC in order to access specific technology to produce nano-materials.

Broadly, “nano” in a certain sense can mean that product scan be made smaller, lighter, stronger or more durable, said Jim Mason, the executive director of the Oklahoma Nanotechnology Initiative - a statewide effort to fast track “nano” research into commercial products.

“For anything that’s manufactured, there’s a nano process to make that better,” said Mason.

In Arkansas, the development of nano-materials is being pursued as a means of economic development, said Greg Salamo, a distinguished professor of physics at UA who has helped shaped academic involvement on the subject.

Nanotechnology programs are supported at UA’s Little Rock and Fayetteville campuses. A $50 million Nanoscale Science and Engineering building at the main campus in Fayetteville is set to open in the fall and will house one of 30 National Science Foundation Materials Research Science and Engineering centers in the country.

Business, Pages 29 on 03/26/2011